Wick Quarry is located next to the Wick Golden Valley between Bristol and Bath.

1892 – site of the Wick Golden Valley Ochre and Oxide Works, with ochre extracted from shallow pits and underground mines in the surrounding area

[Wick Ochre was used to colour the Mall outside Buckingham Palace and was transported all around the world for use as a pigment in pottery, paper, paints and other products]

1970s – depletion of ochre supplies so the site closed 2001 – rehabilitation of the site started

Recent years – the quarry has been converted into a nature reserve and now peregrine falcons have come back year after year to rear their youg

To make the quarry a safer space and to prevent people from falling in some 3.8 million cubic metres of material are needed to reduce the gradient of the slopes.

Ochre – a mix of fine clay and iron oxide, chemically known as anhydrous iron oxide. In Wick Valley red ochre is mined but in other parts of the world yellow ochre can be found. Red ochre was extracted from shallow trenches and mines at Rock Road and was conveyed to the winding shed above the Ochre Works by ponies pulling drams along rails. It was then carried down the ochre works by gravity. The Wick Golden Valley Ochre Works was at the forefront of technology with regards to extraction and processing of the raw material.

It is one of the earliest pigments known to have been used by man.

One of the valuable features of these deposits, noted in several early accounts, was that they had been formed in roughly stratified bands and lenses, and this made exploitation easier than those deposits that occur in ‘pockets’.

- How do you extract materials efficiently?

At this time thee ochre was only being extracted from trenches, a few feet deep.

- What is the depth threshold for extraction?

In 1940, 22 tons of Red Clay were produced as a co-product.

Construction of the works – designed such that the series of adjacent buildings started part the way up the gorge slope at successively lower levels down to the floor of the gorge. The buildings provided four levels at which the processing was carried out, the initial processing being at the top level where the crude ochre was stored in bins with successive processing at lower levels. This reduces the amount of handling required and made for efficient working. The processing of different coloured materials was carried out at vertically distinct sections to avoid one material contaminating another.

An account dated 1895 describes the ochre deposits, in somewhat glowing and, to be shown by experi- ence, to be optimistic terms, as covering about 25 acres and containing that which experts have pro- nounced to be the largest deposit of red and yellow ochre in this country, and probably the world:

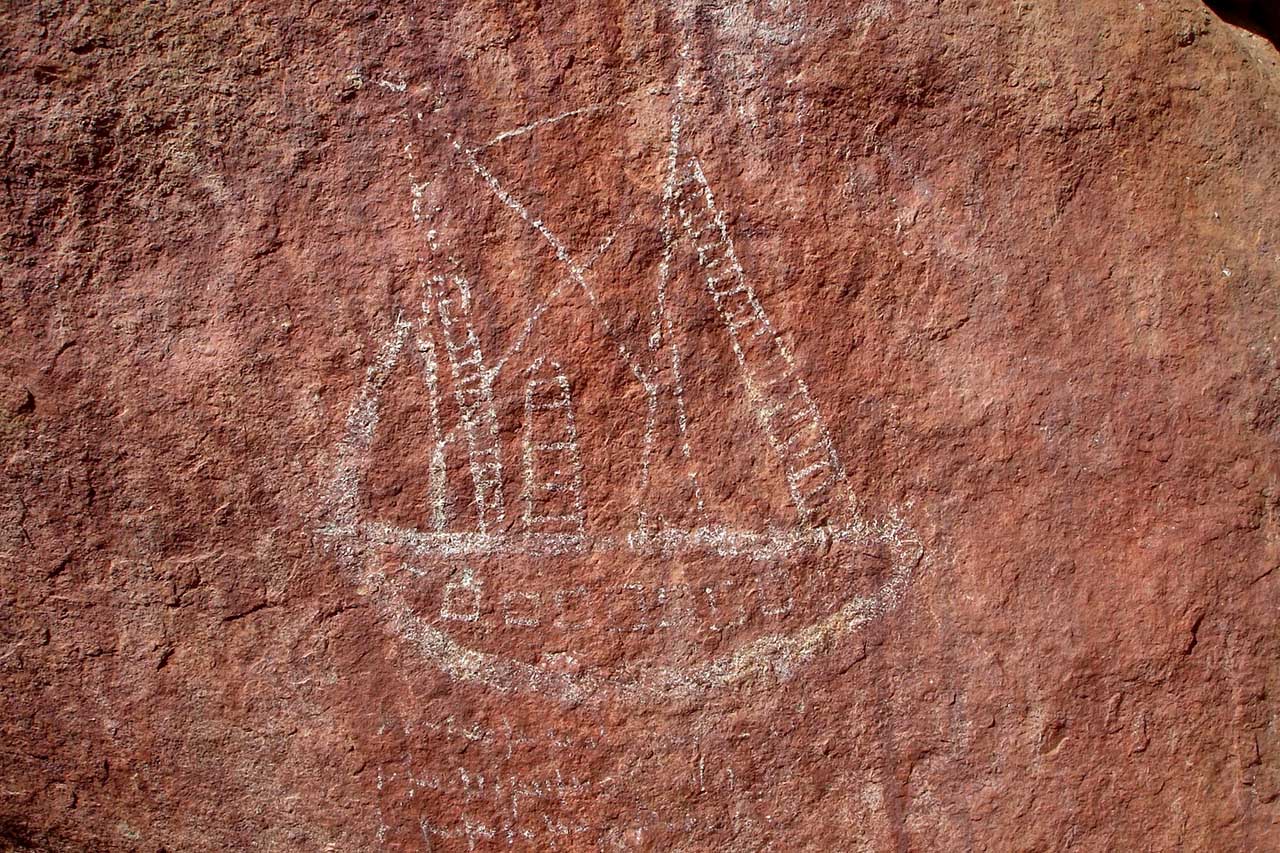

Ochre is the first red paint

Prehistoric people created this ochre fingerprint artwork in Chufín, a cave in western Cantabria,

Spain, about 24,000 to 20,000 years ago.

Ochre extracted by Aboriginals in Western Australia – images suggest traded songlines